Power to X

Power to X or Hydrogen production is an upcoming industry that makes it possible to store and distribute green energy from tex. wind energy. Green energy is the future to ensure we all meet our goals to reduce climate change, and Power to X is the most optimal solution to store and distribute energy.

Challenges

The biggest challenge for this industry is cost, focus is to reduce the cost for Hydrogen and Power to X plants to make it compatible against other energy sources. To be able to produce big volumes of Hydrogen the size of the plants getting relative big, and expensive, and when the goal is to reduce cost often these kind of production facilities are “scrimped” as much as possible, this means lack of space and you get need for a compact and cost effective installation

Solutions

To ensure the most cost effective solution, that take up as little space as possible Wibe Group offer multidiscipline support systems in all material qualities included GRP (fiberglass) where you can combine EIT, HVAC and small bore piping into the same support system. This saves up to 3x the space needed, and reduce the cost with 30-50 % compared to more traditional installations. Wibe Group also offer “low sided” cable ladders, where we also can offer closed hexagonal side profiles that gives a unique high strength and torsion stability.

Use our expertise and experience to show you what we can do with our unique range of products to build the cable management system as compact and cost effective as possible.

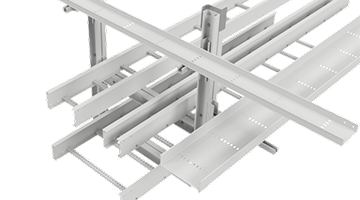

Mita Flex FRP/GRP Support System

A versatile system that provides complete flexibility.

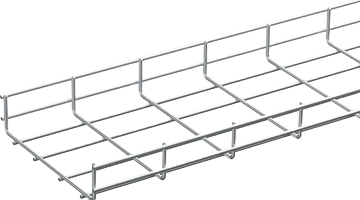

Defem Mesh Trays

Robust, easy-to-install mesh trays with impressive capacity and quality.

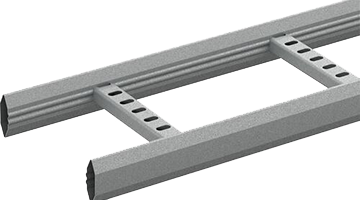

Wibe Cable Ladders

Robust and functional, enabling the same ladder to be used both horizontally and vertically.

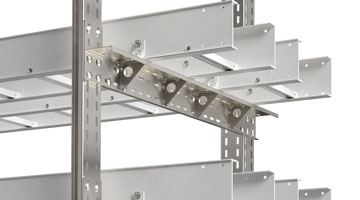

Wibe Flex support system

A flexible support system for all types of environments and disciplines

Need support with your energy or infrastructure project?

Our project sales team is here to help – contact us today.

Product range

Let's start our journey together

Every great project starts with a simple step—getting in touch. Whether you’re ready to start a project or need help calculating the details, we’re here to guide you every step of the way.

Need support with your energy or infrastructure project?

Our project sales team is here to help – contact us today.

Get in touch