Energy & Infra

The energy and infrastructure sectors operate in a challenging environment, where installations are exposed to harsh conditions such as high levels of environmental corrosion, humidity, elevated temperatures, and airborne pollution. Unlike other sectors, Energy & Infrastructure (E&I) can be further subdivided into various sub-segments, including onshore, offshore, tunnel, wind, hydrogen capture.

Challenges

The solutions developed for Energy and Infrastructure are designed to withstand extremely harsh environmental conditions, including corrosion and chemical exposure. Offshore platforms, refineries, and petrochemical plants expose cable support systems to salt water, oil, gas, and chemicals, all contributing to corrosion. These environments also involve extreme temperatures — both high and low—which can impact the durability of cable supports. Additionally, humidity and moisture increase the risk of rust, electrical failures, and structural degradation. The solutions must also be robust enough to support heavy mechanical loads while maintaining structural integrity, and capable of withstanding various vibrations and mechanical stresses. Furthermore, fire and explosion risks are present, meaning cable supports must meet relevant safety standards

Solutions

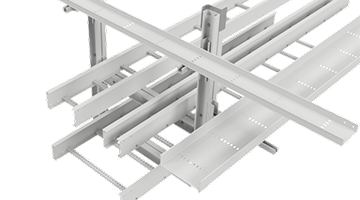

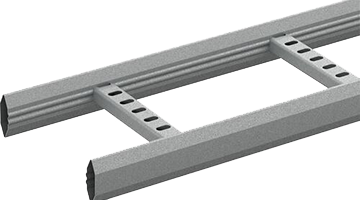

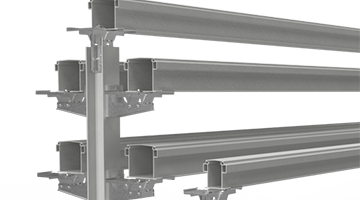

We offer a wide range of cable support solutions tailored for industries including Oil & Gas, Tunnel, Wind, Rail, and CCS. Our solutions include Our unique multidiscipline support systems made of GRP/FRP, or steel cable ladders, trays, form pieces, support systems, and accessories, all designed to meet the specific requirements of each industry. Our products are available in various material types, including stainless steel, galvanised steel, and GRP, ensuring that any solution can be customised with a specific material or a combination of materials to best suit our customers' needs.

As a comprehensive manufacturer of corrosion-resistant industrial cable support products, Wibe Group has the expertise and know-how in various industries,

Mita Flex FRP/GRP Support System

A versatile system that provides complete flexibility.

Defem Mesh Trays

Robust, easy-to-install mesh trays with impressive capacity and quality.

Wibe Cable Ladders

Robust and functional, enabling the same ladder to be used both horizontally and vertically.

GRP GMAX

Offers both posts and troughing in GRP, ensuring a lifetime performance with much less maintenance.

Wibe Flex support system

A flexible support system for all types of environments and disciplines

Need support with your energy or infrastructure project?

Our project sales team is here to help – contact us today.

Engineering

services

We offer expert engineering support through our hubs in Europe and Asia, including:

- Advice & design:

Our team is ready to support you throughout all stages of your project — from the FEED phase to completion and final documentation. We offer design assistance ranging from standard configurations to full project design. Our experts can also provide guidance on material selection, ensuring you achieve the most efficient solution in terms of both performance and cost. - 3D libraries:

STEP files for the Wibe Flex system and related products are available for download.

Cutting & kitting

services

Post-design, we offer Cutting & Kitting services, which include:

- Material production:

We produce materials based on your specifications, using detailed drawings or 3D models. - Efficiency Gains:

Our process accelerates installation, reduces the need for hot work, and minimizes waste, driving both cost savings and environmental benefits. - Pre-assembly:

For further time savings, we also provide pre-assembly services.

On-demand

deliveries

In projects with limited storage, just-in-time deliveries are essential. Our logistics service combines local storage with top regional logistics partners to ensure materials arrive at the right time and place.

Environmental Product

Declarations (EPDs)

We provide EPDs across our entire product range, demonstrating our commitment to transparency, sustainability, and compliance with industry standards. By offering EPDs, we help our customers make informed, environmentally responsible choices.

Wibe Group promise

We provide high-performance cable support systems for applications ranging from commercial buildings to extreme and demanding industrial or offshore environments. Our solutions are designed to meet the demands of all types of projects, ensuring durability and reliability tailored to each specific setting. We pride ourselves on providing the best customer service possible to our clients.

It has been part of the Wibe Group way of doing business since we started almost 100 years ago, and we are convinced that it will never go out of style.

EcoVadis Gold medal

In 2025, Wibe Group AB was awarded the EcoVadis Gold Medal in recognition of our sustainability efforts, placing us in the top 5% of all businesses worldwide and in the top 1% of companies within our industry. This accolade highlights our strong commitment to environmental impact, labour practices, ethics, and responsible sourcing, demonstrating excellence in sustainability and a transparent value chain.

Product range

Let's start our journey together

Every great project starts with a simple step—getting in touch. Whether you’re ready to start a project or need help calculating the details, we’re here to guide you every step of the way.

Need support with your energy or infrastructure project?

Our project sales team is here to help – contact us today.

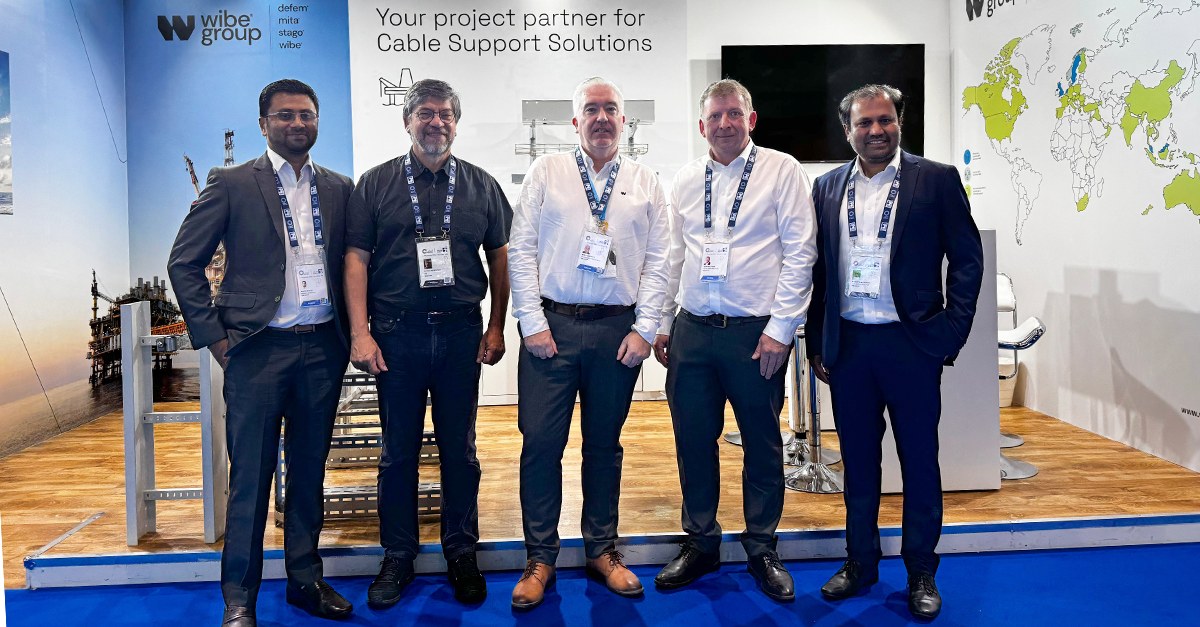

Get in touchOur experts

Bjørn Slettebø

Project Sales Director Energy & Infrastructure International

bjorn.slettebo@wibe-group.com

Mark Forrester

Business Development Manager Energy & Infrastructure Middle East

mark.forrester@wibe-group.com

Marius Eliassen

Business Developer Energy & Infrastructure Scandinavia

marius.eliassen@wibe-group.com