Large industrial and logistics buildings are often built with a frame of steel beam systems. To install cable support in such a structure is a time-consuming task with many steps and components. It also means that you often need to drill into the beam, which negatively affects the strength and can create problems during inspection. The solution is the new BM vertical piece from Wibe, which is easily and smoothly clamped to the beam. Economical and time-saving while improving the working environment for the installers.

The new vertical piece was originally developed by Wibe as a customized solution, together with Eitech in connection with the construction of a large battery factory in northern Sweden. From Wibe Group, Magnus Hilding, product line manager, and Ulf Johansson, senior technical support, were involved in the project.

"We work a lot with customer-unique solutions. Part of the strength of Wibe is that we have that opportunity and can add value to the customer. We always try to sell a solution, a complete system, and there are usually short lead times from idea to finished product. Usually, for example, it's a question of cut-to-size ceiling pendants and anchor rails or that you want the product in a specific color. But sometimes a completely new design is required to solve a customer problem", says Magnus Hilding.

"We use a lot of Wibe products in our projects when working with cable ladders. It's a smooth installation process and it always works."

Customer-specific solutions

When it comes to developing customer-specific solutions, a team of employees at Wibe is always involved in the work. From consultation, prototype development and testing to production and logistics.

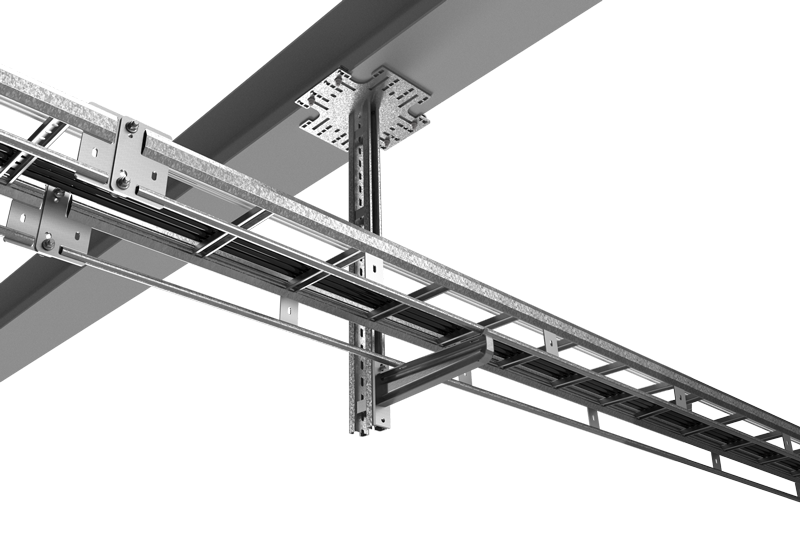

"It started with us receiving a request from Eitech (since June 2024, Eitech is a part of Actemium) that the beams in the current project were painted with fire-retardant paint and therefore could not be tampered with. If the installation means that the beam has to be drilled, the strength is negatively affected, which can create problems in the inspection phase. Since this was also an extremely large industrial project with many kilometers of cable ladders, they also wanted to make the installation as time-efficient as possible."

"We brainstormed ideas together with Eitech, and finally worked out a solution that meant that with just a few components, you could easily clamp the ceiling pendant around the beam, without having to do any damage", says Ulf Johansson.

Wibe then developed a prototype that was tested. The new type of bracket worked very well and with a lead time of a few weeks, the required number could be produced. The new ceiling pendant was then used consistently with good results in the cable routing in the battery factory. From being a customer-specific solution, Wibe has since developed the BM ceiling pendant as a standard product in the range.

Cinis Fertilizer

One of several projects where BM ceiling pendants have later been used is in the construction of Cinis Fertilizer's large production facility on Köpmanholmen in Örnsköldsvik. Cinis Fertilizer AB produces environmentally friendly mineral fertilizer for agriculture, potassium sulfate (SOP), among other things by recycling waste products from the pulp and paper industry and from the manufacture of electric car batteries.

The patented technology uses half as much energy as today's production methods and the result is a mineral fertilizer with a very low carbon footprint. The groundbreaking ceremony for the facility on Köpmanholmen was held in mid-February 2023. We Construction built the facility, which consists of a process building with a technical section, offices and salt storage. In total, the process building has a ground area of approximately 2025 square meters and 6 ½ floors. Eitech, now Actemium, was responsible for installing electricity and lighting in the process room.

"This is an industry where there is a very high amount of salt in the process itself and our client therefore did not want us to drill or do any other damage to the steel beams as this would destroy the protective fire protection paint", says Pierre Carlström, lead installer Actemium.

"It couldn't be easier and it was really quick. We probably saved up to 60 percent in time compared to if we had installed the vertical piece in the traditional way."

Large time savings

Pierre had worked at the battery factory before and had seen how the installers of the cable ladders could install them quickly and easily with the new ceiling pendant. The project at Cinis Fertilizer involved upwards of 1000 vertical pieces to be installed and with the large quantity it was really important to find solutions that saved time.

"We chose to use BM vertical pieces here too and it worked perfectly. Previously, when we attached vertical pieces, we first had to pre-drill, then drill with a larger drill bit and then thread. Now we could instead pre-assemble two clamps and then hang on the vertical piece and the new bracket. All that was required was a wrench and a fixed ring wrench. It couldn't be easier and it was really quick."

"We probably saved up to 60 percent of our time compared to if we had installed the vertical pieces in the traditional way. Saving time is an advantage both financially and in terms of the work environment, as the installers minimize the time they spend working with their hands above shoulder height. We will use BM vertical pieces in several projects in the future, that's for sure", says Pierre and continues:

"We use Wibe a lot in our projects when we work with cable ladders. They have a good range and there are always many possibilities with their products. It's easy and it always works."

Wibe BM Vertical Piece

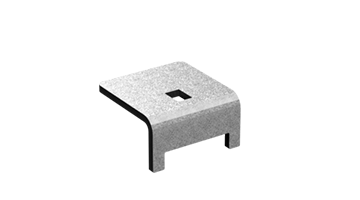

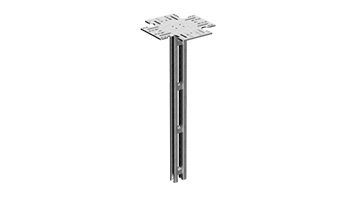

BM vertical pieces are adapted for I-beams with a width of 200-300 mm, and are a further development of our strongest ceiling pendants 20, 20F and 20FS. The BM pendant has a large ceiling plate that is placed right under the beam, and then clamped to the beam's flange with a screw and clamp set. Specially designed grooves in the ceiling plate lock the clamp and prevent the pendant from moving or coming loose. Installation is relatively simple without cutting and drilling, which means great time savings, and involves few components, which in turn means simpler logistics.

The BM vertical piece is available in hot-dip galvanized steel for C4 environments, in lengths between 0.5 and 6 meters. Clamps and screw set are ordered separately and are available in four variants for material thicknesses between 0 and 40 mm.

Related products

Cinis Fertilizer

- Location

- Örnsköldsvik, Sweden

- Date

- 2023-2024

- Segment

- Industry

- Installer

- Actemium

- Products

- Wibe BM Vertical Piece for quick installation in beam structures, plus cable ladder KHZ.