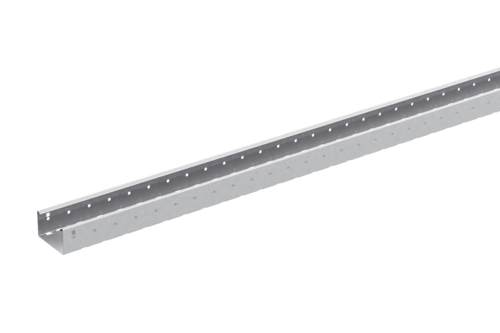

KG281 Perf tray 60x100 T=0.8 L=3m PG

Item number

CSU08607202

Local code:

*

GTIN:

8720871004908

Description:

KG281 Perf tray 60x100 T=0.8 L=3m PG

Properties

Status product

Product status

Commercialized

Commercial and Web

Short description

KG281 Perf tray 60x100 T=0.8 L=3m PG

Medium description

Stago - KG281 perforated cable tray 60x100mm - T=0.8mm - L=3m - pre-galvanized

Length

3000 mm

Width

100 mm

Height

60 mm

Material

Steel

Material type or surface treatment

Pre-galvanized

Corrosion class

C2

Base

Activity

Cable support systems

Product family

Cable trays

Brand

Stago

Range

KG281

GTIN

8720871004908

ETIM (EC000047-Cable tray/wide span cable tray)

Height (EF000040)

60 mm

Width (EF000008)

100 mm

Material thickness (EF000386)

0.8 mm

Length (EF001438)

3000 mm

Useful cross section (EF005140)

6000 mm²

With cover (EF007965)

No

Side wall perforation (EF001122)

Yes

Mounting perforation in bottom (EF004545)

Yes

NATO (EF006059)

No

Model (EF000010)

Without connector

Wide span model (EF006397)

*

Suitable for circuit integrity (EF007806)

No

Material (EF002169)

Steel

Stainless steel, pickled (EF006388)

No

Material quality (EF001257)

Other

Surface protection (EF000139)

Continuously galvanized

Colour (EF000007)

*

RAL (EF000116)

*

Weight (EF000167)

1.51 kg/m

Max. safe working load according to IEC 61537 (EF016305)

* N/m

Span between supports according to IEC 61537 (EF015363)

* mm

Load test type according to IEC 61537 (EF015362)

Type I

Logistic

Pack 1 type

Each

Quantity pack 1

1

Weight pack 1

4.54 kg

Length pack 1

3000 mm

Width pack 1

100 mm

Height pack 1

60 mm

Pack 4 type

Pallet

Quantity pack 4

100

Weight pack 4

454 kg

Length pack 4

3000 mm

Width pack 4

860 mm

Height pack 4

730 mm

Customs code

73089098

Net weight

4.54 kg

Country of origin

NL

Certification

ETIM class

EC000047

Environmental

GWP Total A1-A3

11.21 kgCO2e

Product downloads

| Corrosion class | C1 | C2 | C3 | C4 | C5 | CX | |

| Environmental corrosion | Very low | Low | Average | High | Very high | Extreme | |

| Examples of environments | Indoors | Heated areas with arid atmosphere and insignificant quantities of pollutant, e.g. offices, shops, schools and hotels. | Non-heated areas with fluctuating levels of temperature and humidity. Few instances of condensation and low levels of airborne pollution, e.g. sports halls and warehouses. | Average levels of humidity and some airborne pollution resulting from production processes, e.g. breweries, dairies, laundries. | High humidity and considerable airborne pollution as the result of production processes, e.g. chemical plants, swimming pools and dockyards. | Buildings with almost permanent condensation and with high pollution | Industrial buildings with extreme humidity and aggressive atmosphere. |

| Outdoors | Atmospheres with low levels of airborne pollution. Rural areas. | Atmospheres containing some salt or average levels of air-borne pollution. Urban and light industrial areas. Areas affected by coastal conditions. | Atmospheres with average salt content or discernible levels of airborne pollution. Industrial and coastal areas. | Industrial areas with high humidity and aggressive atmosphere, and coastal areas with high salinity | Offshore areas with high salinity, industrial areas with extreme humidity, and aggressive atmospheres, sub-tropical or tropical atmospheres. | ||

|

Wibe Group designation

Exceeds requirements. Extremely high durability.

Recommended very high durability ( >20 years)

Possible alternative. High durability (10-20 years) |

Electro-galvanized (EG) |

|

|

||||

| Pre-galvanized (PG) |

|

|

|

||||

| Zinc+ (Z+) |

|

|

|

|

|||

| Hot-dip galvanized (HDG) |

|

|

|

|

|

||

| Zinkpox (ZP) |

|

|

|

|

|

|

|

| Stainless steel AISI 304L(SS304) |

|

|

|

|

|

|

|

| Stainless steel AISI 316L (SS316) |

|

|

|

|

|

|

|

| Glass Fibre Reinforced Polymer (FRP/GRP) |

|

|

|

|

|

|

|

This table shows estimated values.

For more detailed advice, please contact technical support at Wibe Group